Researchers at Yonsei University in South Korea have developed a new type of flexible OLED display, capable of stretching up to 70% of its original length while maintaining about 80% of its brightness after 300 stretching cycles. This breakthrough could redefine the future of flexible electronics, paving the way for stronger, more adaptable, and brighter devices. The innovation relies on a sequential coating technique that enables a more stable and efficient device compared to traditional lamination-based OLEDs.

A New Generation of Flexible OLEDs

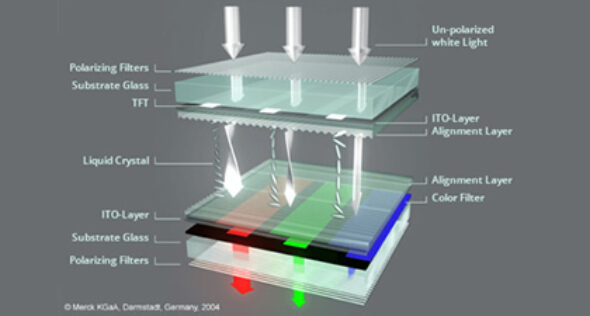

Traditional flexible OLEDs, also known as intrinsically stretchable OLEDs (IS-OLEDs), often suffer from performance degradation due to incompatibility between solvents and laminated layers, which can lead to defects and delamination. The new method developed by the Korean research team overcomes these issues, improving elasticity, durability, and brightness stability. The new IS-OLEDs can reach a peak brightness of 3,151 nits with an efficiency of 5.4 cd/A, maintaining performance even after repeated mechanical stretching.

Sequential Coating: A Simpler and More Promising Approach

The sequential coating method represents a major step forward compared to the complex multilayer lamination techniques used so far.

This more streamlined and controlled approach minimizes the risk of defects during the deposition of organic materials, simplifying manufacturing and making it more scalable for mass production of flexible OLED panels. In the long term, this could help reduce production costs and accelerate the commercial adoption of affordable, efficient, and durable flexible OLED devices.

Future Improvements and Material Optimization

According to the researchers, further improvements can be achieved by refining the choice of cathode materials and optimizing the Electron Transport Layer (ETL) — the layer responsible for conducting electrons within the device. By fine-tuning the thickness and chemical composition of the ETL, OLEDs could reach even higher levels of brightness, efficiency, and lifespan, enabling new standards for next-generation flexible displays.

Industrial Impact and Applications

The potential applications of this technology extend far beyond mobile devices. The new flexible IS-OLEDs could be used in:

- Wearable smart devices, such as biometric wristbands, interactive fabrics, and medical sensors;

- Foldable or rollable displays for smartphones, tablets, and laptops;

- Flexible lighting systems adaptable to curved or architectural surfaces;

- Dynamic digital signage and advertising, with customizable, lightweight designs.

The breakthrough has already attracted international industrial interest, and reports suggest that this research has become a target of industrial espionage, highlighting its strategic and economic importance.

Toward the Future of Elastic Electronics

This innovation marks a major step toward the next generation of flexible electronics, where screens, sensors, and lighting surfaces can bend, stretch, and deform without losing visual quality. IS-OLED technology stands at the intersection of materials science, electronic engineering, and industrial design, with the potential to transform how we build, use, and experience technology in the years ahead.